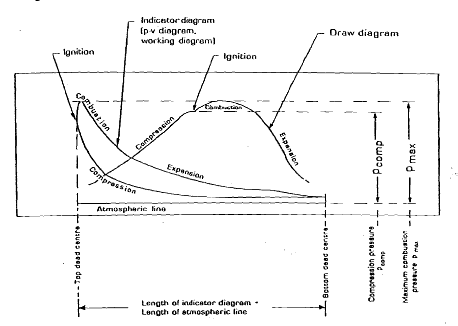

I) Calculation of engine Power with Indicator diagram

For engines with indicator drive or MIP-equipment, we can take the indicator diagram which can be used to find the Mean Indicated Pressure (MIP). Dont get confused between MIP and MEP. Former is the Indicated mean pressure while MEP is the effective pressure availabel after friction losses in the shaft.Calculation of the indicated and effective engine power consists of the following steps:

Calculate:

- The mean indicated pressure, pi

- The mean effective pressure, pe

- The cylinder constant, K

- The indicated engine power. Pi

- The effective engine power, Pe

-The mean indicated pressure, Pi

Mean Indicated Pressure, pi

Pi (bar) = AL x Cs

A = A is the area of the Indicator diagram measured with a Planimeter in mm^2

Cs = Spring constant of the drive in mm/bar (vertical movement of the indicator stylus (mm) for a 1 bar pressure rise in the cylinder)

L = length of the indicator' diagram (atmospheric line)

The mean effective pressure, pe

(for BMW engines)pe = pi - kt (bar)

where

kt = the mean friction loss

The mean friction loss has proved to be practically independent of the engine load. By experience, kt has been found to be:

S26MC: kt = 1.50 bar

L35MC: kt = 1.25 bar

S35MC: kt = 1.15 bar

L42MC:kt = 1.10 bar

S42MC: kt = 1.00 bar

Cylinder Constant, K

The cylinder constant, K is determined by the dimensions of the engine, and the units in which the power iswanted.

For power in kW : = 1,30900 x D^2 x S

For power in BHP : = 1,77968 x D^2 x S

where:

D (m) = cylinder diameter

S (m) =piston stroke

The indicated engine power, Pi

Pi = K x n x pi (ikW or ihp)where

n (rpm) = engine speed.

The effective engine power, Pe

Pe = K x n x pe (kW or bhp)where

n (rpm) = engine speed.

This effective power is used to calculate the SFOC of the engine. Click here to know how to calculate SFOC of engine

II) Power calculation without Indicator Diagram

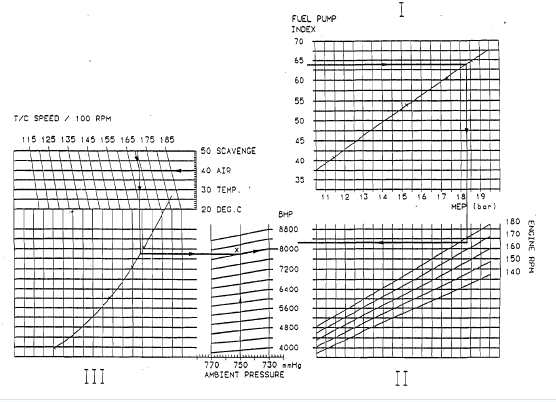

The estimation is based on nomograms involving engine parameter measurements taken on testbed. the graphs are provided in the manual

1) Fuel Pump Index method

The fuel pump index is used to find out the mean effective pressure from the nomogram graph. Again form the graph, the mep at a specific speed gives the engine bhp.

This method should only be used as a quick (rough) estimation, because the fuel oil, as well as the condition of the fuel pump, may have great effect on the index. In particular, worn fuel pumps or suction valves tend to increase the index, and will thus result in a too high power estimation.

Chart I: draw a horizontal line from the observed fuel pump index to the nomogram curve, and then a vertical line down to the observed engine speed on Chart II. From this intersection a horizontal line is drawn to the effective engine power scale. (This method is specific for some engines. many other parameters are included to calculate the BHP in bigger engines)

This effective power is used to calculate the SFOC of the engine. Click here to know how to check the SFOC

This effective power is used to calculate the SFOC of the engine. Click here to know how to check the SFOC

So some factors are not included in calculating the BHP of the engine. Click here to view another example of BHP calculation using more parameters (will be updated soon).

(Graph is specific for a type of engine)

2) Turbocharger speed method

This method id more accurate than the Fuel pump index method. Chart III: draw a horizontal line from the observed tscav value and an inclined line from the observed turbocharger speed. From the intersection point, draw a vertical line down to the nomogram curve and then a horizontal line to the vertical tine from the observed ambient pressure (point x in the ambient pressure scale). Finally, a line is drawn parallel with the inclined 'ambient pressure correction' lines. The effective engine power can then be read on the scale at the right hand side, i.e. 8,000 bhp.

This effective power is used to calculate the SFOC of the engine. Click here to know how to calculate SFOC of engine

If you like our article, share it with your friends and VISIT OUR FACEBOOK PAGE AND LIKE IT (click here) to get all updates from us.

This effective power is used to calculate the SFOC of the engine. Click here to know how to calculate SFOC of engine

If you like our article, share it with your friends and VISIT OUR FACEBOOK PAGE AND LIKE IT (click here) to get all updates from us.