|

Sr. No.

|

Name of the Medical Examiners / Year of Approval

Reference No.

|

Full Style of Facility

.

|

|

1

|

Dr. A. Harigopal Subudhi

Year-2001

|

Sun Clinic, 47, Vaju Kotak Marg,

GPO, Near Govt. Shipping Officer, Fort, Mumba-400001 Phone-22340226 /

22703557 Branch:

Sun Clinic, Shop No.1, Rabia Manzil, Dawood Baug Lane, Near

Station, Andheri(W),Mumbai-400058

|

|

2

|

Dr. Arun V. Shetty

Year-2002

|

Cumballa Hill Hospital & Heart Inst., 93/95, August Kranti

Marg, Mumbai-400 036

|

|

3

|

Dr. Ashish Chaudhari

Year-2001

|

Marine Medical Services, Room No.210/211, Mint Chamber,

|

|

4

|

Dr. B. L. Sundarka

Year-2001

|

Twinkle Apts. Off. Link Road, Andheri (W), Mumbai - 400 053.

|

|

5

|

Dr. Corinne Idnani

Dr. Suresh Idnani Year-2001 |

Dr. Idnani's Diagnostic Laboratory, 4, Kalpana, 2nd

|

|

6

|

Dr. D. P. Modi

Year-2001

|

The Shipping Corporation of India Ltd., Shipping House, Madame

Cama Road, Nariman Point, Mumbai -

400021.

|

|

7

|

Dr. H. S. Bhatia

(MMC Regn No.19883)

Year-2001

|

(Two facilities)

Clinic: 5-A, Meghji Bhavan, 1st floor, Barrack Road, Above Cafe

Cecil, Behind Metro Cinema, Mumbai-400

020

604/B,

Andheri (W),

Mumbai 400 053.

|

|

8

|

Dr. J. K. Manghani

Year-2001

|

Clinic: The Surgery, 958, Adarsh Nagar, New Link Road, Andheri

(E), Mumbai-400 102

Phone-2674 2072 / 5677 7251

|

|

9

|

Dr. J. H. Major

Year-2001

|

C/o Maritime Association of ship owners Shipmanagers &

Agents, 4, Shoorji Vallabhdas Marg, Ballard Estate, Mumbai - 400 038

|

|

10

|

Dr. J. Mathew

Year-2001

|

Sea Bird Health Foundation, A Wing 102, Heritage Plaza,

Telli Cross Lane, Near Andheri (E) Stn., Mumbai-400

069

|

|

11

|

Dr. J. M. Rele

Year-2001

|

1,

Phone-2380 3636 /2380 373 |

|

12

|

Dr. K. A. Vazirani

Year-2001

|

Clinic- Jaya Diagnostic Centre, 1st fl., Maneckji Wadia

Bldg.,Opp. Mumbai University, Fountain, Mumbai-400

023.

|

|

13

|

Dr. Mervyn S. Abreo

Year-2001

|

Clinic: Crresshhha Polyclinc, 1-A, Devi Ekveera, Next to

Chinai College, Old Nagardas Road, Andheri (East), Mumbai400 069

Phone-(R) 2445 5542/ 56989770

|

|

14

|

Dr. M. P. Rele

Year-2001

|

Clinic: 1,

Phone-2380 3636 /2380 373 |

|

15

|

Dr. Mahendra Desai

Year-2001

|

Green Cross, Immuno-Diagonostic Centre & Pothology Lab,

Kamleshwar, Opp.Laxmi Narayan temple, 40,

|

|

16

|

Dr. M. K. E. Menon

Year-2001

|

Clinic: Kaifak Medicare, 214, Maker Chambers- V, Nariman Point, Mumbai-400 021

Phone-2204 4385 / 2287 3555

|

|

17

|

Dr. Nathwani

Year-2001

|

Clinic: Dr. Nathwani's Medical Clinic, Gita-B, 2nd fl, Gamdevi,

Mumbai-400 007

|

|

18

|

Dr. Ranbir Singh

Year-2001

|

Clinic: 33/37, Rex Chamber, W.H. Marg,

Mumbai-400 001

Phone-56318446 - 47 5 92 6151/52

|

|

19

|

Dr. S. Chowdhury

Year-2001

|

Boon-Bon Diagnostic Centre, 1 Ground Floor, Shivam Apts.,

plot No. A-1,142/143,

Phone -2634 5700

|

|

20

|

Dr. S. S. Shetty

Year-2001

|

Dr. Shetty Clinic, Ship No.4, Puspa Bhavan, Opp. Telephone

Bhavan, Colaba, Mumbai-05

|

|

21

|

Dr. V. Z. Belani

Year-2001

|

Blue Shield Med. Clinic, 1st

First Floor,

|

|

22

|

Dr. V. Z. Belani

Year-2001

|

Blue Shield Med. Clinic, Andheri Clinic:

7th

Phone-28235050 / 28223637/28235949

|

|

23

|

Dr. M. V. Aswani

Year-2001

|

Chevron Manning Services Ltd., C/o. Northern Marine Management

India Pvt. Ltd, 18 Sprott Road, Ballard Estate, Mumbai-400 001.

Phone-22382000

|

|

24

|

Dr. A. A. M. Hajwane

Year-2001

|

13-14, Rex Chambers, Ground Floor, W.H. Marg, Bellard Estate,

Mumbai-400 001

Phone-2265 5233 /34

|

|

25

|

Dr. Hozic D. Kapadia

Year-2001

|

Shop No. 4/12, Kavarana Terrace, Opp. Gloria Church, Byculla, Mumbai - 400 027.

Phone-23711060

|

|

26

|

Dr. A. C. Kulkarni

Year-2001

|

Clinic: 3-A, Siddhi Vinayak Chambers, Opp. MIG Club,

Bandra (E), Mumbai-400 051

Phone-2642 3428 / fax-2642 1969

|

|

27

|

Dr. A. M. Joglekar

Year-2001

|

Marine Occupational health Centre, Plot No. 214/5, Prem- Trishna,

Off MC Rd, Sher-e-Punjab, Andheri (E), Mumbai

- 400 093.

|

|

28

|

Dr. (Mrs.) Radha N. Chowgule

Year-2001

|

Phone-2386 5749 M-9821320886

|

|

29

|

Dr. Sudhir Medhekar

Year-2002

|

Clinic: Skin & V.D. Specialist, Norden Hospital, 34, Shanti

Niwas Chaman House, Near Sion Bus Depot, Sion, Mumbai-400 022. Telephone- 24072642

|

|

30

|

Dr. Rajiv V. Tripathi

Year2002

|

Clinic- Rajiv Medical Centre,

Sriraj View, Sanapati Bapat Marg, Matunga (West), Mumbai-400 018

|

|

31

|

Dr. Vijay Shetty

Year-2002

|

Clinic-Ocean Grant Marine Medical Clinic (Shetty Clinic) 9A

Telephone NO. 24221125

|

|

32

|

Dr. Anil Kumar Arora

Year-2002

|

Clinic: B.B.C. 12/14, Vajukotak Marg, Fort, Mumbai-400 001.

Phone- 22610314 / 22695072

|

|

33

|

Dr. R. H. Kewalaramani

ACMO-Offshore

Year-2002

|

Oil & Natural Gas Corpn. Ltd., Mumbai Regional Business

Centre, Medical Section,128, Vasudhara Bhavan, Bandra (W), Mumbai-400 051

|

|

34

|

Dr. D. Shome

DGM (Medical)_Ops

Year-2002

|

Oil & Natural Gas Corpn.Ltd., Mumbai Regional Business

Centre, Medical Section, 128, Vasudhara Bhavan, Bandra

(W), Mumbai-400

051. Telephone-2 6429945

|

|

35

|

Dr. G. K. Venkatesh

Year-2002 |

Vijaya Clinic, 4,

Telephone-37714960 / 23781290 |

|

36

|

Dr. S. Potdukhe

Sr. Medical Officer

-----------

|

Oil & Natural Gas Corpn.Ltd., Mumbai Regional Business

Centre, Medical Section,128, Vasudhara Bhavan, Bandra (W), Mumbai-51. phone - 26599753

26605719

|

|

37

|

Dr. R. K. Lakhani

Year-2002 |

Clinic-Veena Nagar Health Care Centre, 24/A-4/2, Veena Nagar,

L.B.S. Marg, Mulund (W),

Mumbai-400 080 Phone-25603272 / 67551115 |

|

38

|

Dr. Girish H. Mistry

Year-2002

|

Clinic: Sai Marine Clinic, 13/21, Fatemi Manzil, 1st,

Mumbai-400 002. Telephone- 2207 0423 |

|

39

|

Dr. Kirti Kumar R. Desai

Year-2002 |

Narayan Leela Clinic Shop No.12, Radhika Niwas Co.Op.Hsg.

Society, Sir M.V.Road, Opp. Punjab Travels, Andheri(E), Mumbai-400 069

|

|

40

|

Dr. H. G. Sahijwala (MMC Regn No.50239)

Year-2001 |

Clinic: 2, Pushpa Bhuvan, Opp. Colaba Tepehone Bhavan,

Colaba, Mumbai-400 005

Phone-22872274

|

|

41

|

Dr. M. A. Patankar

Year-2001

|

A to Z Diagnostic Centre, Opp. Our Lady of

Mumbai -400002.

phone-2208 8263 / 22010484

|

|

42

|

Dr. S. Shahzeb Khan

Year-2001

|

Clinic: Colaba Medicare Centre, 1-A, Kulsum Terrace, Walton

Road, Colaba Causeway, Muimbai-400 005

Phone-2284 3597/2850168

|

|

43

|

Dr. Dushyant J. Barfiwala

Year-2001

|

Flat No.3, Villa Maria,

Mumbai-400052.

Phone-6006069 / 6004715

|

|

44

|

Dr. Mrs. Neelam Singh

Year-2001

|

Ujala Apt. 3rd floor,

Phone-22615699 / 22318446 / 22318447

|

|

45

|

Dr. Ashfaq Ahamed Uhbaray

Year-2001

|

Clinic:

|

|

46

|

Dr. (Mrs.) Seema B. Gurnani

Year-2001

|

Clinic-India House Path-Lab (Diagonistic Centre),

Phone-23860046 / 23867094

|

|

47

|

Dr. K. C. Bhatia

Year-2002

|

Medical Superintendent, P&O Cruises, P&O Nedlloyd (I)

Pvt.Ltd.,Forbes Bldg., 3rd Floor, Charanjit Rai Marg, Fort, Mumbai-400 001.

Telephone-22332002

|

|

48

|

Dr. Lalita Kedia

Year-2002

|

Keshav Medical Centre, 43, Bajaj Bhavan,4th Floor, 226, Nariman

Point, Mumbai-21 Telephone-2853507/08/09/10

|

|

49

|

Dr. H. K. Goswami

Year-2002

|

Modern Polyclinic, Modern House, 10,

Mumbai-400005. Telephone- 22844915 |

|

50

|

Dr. Rajkumar. V. Tripathi

Year-2002

|

Clinic: Sriraj View, Ground flr., Senapati Bapat Marg, Matunga

(West), Mumbai -400 016.

Telephone- 24382759

|

|

51

|

Dr. F. E. Palia

Year-2002

|

Clinical Diagnostic Centre,A-2,

Mumbai-400 036 Telephone- 23684764 / 23684765 |

|

52

|

Dr.Iqbal B. Bagasrawala

Year-2002 -

|

Clinic Ground -96-Asoka Shopping Centre, L. T. Marg, G.T.

Hospital Complex, Mumbai-01. Phone- 2267 8360

|

|

53

|

Dr. S.H. Mashru

Year-2001

|

Clinic: 404/AA Waghwadi, 1st Floor,

|

|

54

|

Dr. Vaseem M Peshimam

Year-2003

|

Clinic: Essem Medical Centre,5/F,

|

|

55

|

Dr. Mitosh H. Ruparel

Year-2003

|

Modern House,

|

|

56

|

Dr. Hazel Sunil

Year-2001

|

Sea Bird Health Foundation 133, Galleria,

|

|

57

|

Dr. Sisir Kumar Sinha

Year-2001

|

Marine Medical Clinc, 272/3, Lucky House, Gr. Floor,

Phone 22665928 22691745 Nerul-9223230290.

|

|

58

|

Dr. Sonia Subin

Year-2003

|

Seabird Health Foundation A-301 Vertex Vikas, Opp. Andheri

Station, Andheri (E),

Mumbai-400069 Phone- 26821823

|

|

59

|

Dr. G. H. Kuchan

Year-2003

|

Clinic - ONGC, 127, Vasudhara Bhavan, Bandra (East), Mumbai-400 05.

Phone-2659 9680

|

|

60

|

Dr. Nirmala Lulla

Year-2001

|

Modern House,

|

|

61

|

Dr. Sunil J. Sankhe

Year-2003

|

Medicare Diagnostic Centre, 51/2405, Gandhi Nagar, Brandra (east) Mumbai-51

Phone -26405639/ 26456742

|

|

62

|

Dr. J.T. Shah

Year-2002

|

Sandeep Clinic, 6, Vasant Apartment, Near "D"

jambo-Darshan & Hotel Regency, Andheri (East) Mumbai-69 Phone-26820212

|

|

63

|

Dr. S. S. Bhoira

Year-2003

|

Lambe Diagnostic Centre, Shop No.3,

|

|

64

|

Dr. Abdul Karim M. Naik

Year-2003

|

Modern Diagnostics, 6 Merchant Building,

Ph.-23736872 / 23718663 / 23755572

|

|

65

|

Dr Narendra H. Chaudhari

Year-2003

|

Clinic: Marine Medical Services, Room 210/211 Mint Chamber,

|

|

66

|

Dr. Usha K. Jain

Year-2004

|

Jain Medical Centre, Flat No.102, 1st Floor,

A-wing, Sani Shopping Cnetre, Opp. Jogeshwari Rly. Stn. (west) Mumbai-400 102. Phone -2678 9090.

|

|

67

|

Dr. Vijay M. Gandhi Year-2004

|

Clinic : 3, Jasvile, 9, New Marine Lines, Mumbai-400 020.

Tel No. 2008808/2311598/99 |

|

68

|

Dr. F. E. Palia

Approved by M.S. Notice NO.13/2002

|

New Clinical Addressed: Clinical

Diagnostic Centre, Wicel administrative Bldg. Gr. Floor, Plot No.F-11 &

F-12/1. Opp. SEEPZ Main Gate, MIDC (MAROL)

|

|

69

|

Dr. Duleep D. Bhonsale

Year-2004

|

Dr. Bhonsale’s Diagnostic Centre, 2, Jawaharban C.H.S. Sahyog

Nagar, Lokhandwala Road, Four Banglows, Opp. Dr. Mandke’s Heart Hospital,

Andheri (West) Mumbai-53

Phone No.2639 4507 / 2632 2006.

|

|

70

|

Dr. Ajit Bhaskar Oke

Year-2004

|

Clinic: National Medical Centre,3/3, New Sion Co-Opp. Society,

Rd.-24 Sion (West), Mumbai-400 022

|

|

71

|

Dr.K.F. Gurwara

Year-2005

|

Phone 23634510- fax-56648016 |

|

72

|

Dr. H.S. Wagle

Year-2005

|

Mumbai-400 004. |

|

73

|

Dr. Prashant T. Mane

Year -2005

|

Clinic: Modern House,

|

|

74

|

Dr. Abha Shroff

Year-2005

|

Clinic: DIsha Pathology Services,

Bandra (W) Mumbai-400 050. |

|

75

|

Dr. Porus Hozie Kapadia

Year-2005

|

Clinic: Kavarana Terrace, Opp: Gloria Church,

Mumbai-400 027.

|

|

76

|

Dr. Aleem A. Siddiqui

Year-2005

|

Clinic: Gulshan Medicare, 39/43,

|

|

77

|

Dr. Pradull S. Jain

Year-2006

|

Clinic: Blue Shield Medical Clinic, 702 & 703 Drystal Plaza,

Phone-5678 1400 (3 Lines)

|

|

78

|

Dr. Bhagwan D. Belani

Year-2006

|

Blue Shield Clinic, Next to Regal Cinema,

|

|

79

|

Dr. Punita Masrani

Year -2006

|

Clinic: MedSolutions, 78B, Pankaj Mansion, Ground Floor, Dr.

Annie Besant Road, Worli, Mumbai-400

018

Phone-2490 1066

|

|

80

|

Dr. Vipul Masrani

Year-2006

|

Clinic: Med Solutions, 78 B, Pankaj Mansion, Ground Floor,

Dr. Annie Besant Road, Worli, Mumbai-400

018

Phone-2490 1066

|

|

81

|

Dr. M.S. Alva

Year-2006

|

Clinic-Dr. Alva;s Clinic, 543, N.M.Joshi Marg, Mumbai-400 011

Phone-2307 5932 / 2309 9746

|

|

82

|

Dr Ratan B. Datwani,

Year 2006

|

M/s, Dr. Ranbir Singh's Clinic,

411/413 Sai Commercial Bldg., B.K.S. Devsi Marg, Govandi, Mumbai-400 088. Phone 6755 4551 / 2548 2458 |

|

83

|

Dr. Yogesh K. Kantharia

Year 2005 |

Clinic-Mount Mary Clinic,

Mumbai-400 050 Phone 2640 7455 |

|

84

|

Dr. Anil Mehra

Year 2005 |

Clinic- 41, Pali Hill Bandra,

Mumbai-400 050 Phone -2649 1537` |

|

85

|

Dr.Yatin S.Patel

Year -2010 |

Leela Polyclinic & Diagnostic Centre,

11, Buildarch Terrace CHS, 1st Floor, Mahim (West), Mumbai-400 016. Ph.No.24444 8894 Tel fax- 24444 8892 |

|

86

|

Dr.Sunil Ramotar Saraf

Year -2010 |

Saraf's Diagnostic Centre,

103,104, Vyom Arcade, Tejpal Scheme Road No.5, Off.Subash Road, Vile Parle(East), Mumbai-400 057.Tel No.2683 3441/2683 442 Telefax:2682 7478 |

|

87

|

Dr.Sonali Jugalkishore Pitty

Year 2010 |

Saraf's Diagnostic Centre,

103,104, Vyom Arcade, Tejpal Scheme Road No.5, Off.Subash Road, Vile Parle (East), Mumbai-400 057. Tel No.2683 3441/2683 442 Telefax:2682 7478 |

|

88

|

Dr.Rajanish Mishra

Year 2010 |

Mangala Diagnostic Centre,

1-11, Symphony Apartment, Azad Road, Next to BMC Office, Andheri, Mumbai-400 069. Tel No.2684 5076/2682 7197 Fax No.2683 8710 |

|

89

|

Dr.Seema B.Gurnani,

(MMC Regn No. 55518)

Year 2010 |

India House Path-Lab,

Neelam Centre Industrial Premises Co-op Society Ltd., 302, 'A' Wing, Neelam Centre, 3rd floor, Hind Cycle Marg, Worli, Mumbai-400 030. |

|

90

|

Dr. Radha N.Chowgule,

(MMC No.55624)

Year 2010 |

India House Path-Lab,

Neelam Centre Industrial Premises Co-op Society Ltd., 302, 'A' Wing, Neelam Centre, 3rd floor, Hind Cycle Marg, Worli, Mumbai 400 030. |

|

91

|

Dr. Bharati J.Rele

(MMC Regn No.64785)

Year 2010

|

Rele Clinic,

Gita Bldg., "A" Wing, 2nd Floor, Pandita Ramabai Road, Gamdevi, Mumbai-400 007. |

|

92

|

Dr. Ashish Chaudhari

(MMC Regn No.72254)

Year 2010 |

Marine Medical Services,

301, Vishwananak Apartments, Chakala, Andheri (East), Mumbai-400099. Tel No. 022-6590 1052 |

|

93

|

Dr. Saleh K. Dhansura (MMC Regn No.073323)

Year 2010 |

Marine Medical Services,

210/211, Mint Chamber, 45/47, Fort, Mumbai-400 001 Tel No.022- 2261 1213 |

|

94

|

Dr. Chirag Janardan Patil, (MMC Regn No.2006/12/3768)

Year 2010 |

Blue Shield Medical Clinic,

First Floor, Mumbai-400001. Tel No.022-2287 3419, 2287 3449 |

|

95

|

Dr. Saurabh Goel

(MMC Regn No.62601)

Year 2010

|

Fayth Clinic,

Next to CITI Financial, Shankar Ghanekar Marg, Prabhadevi, Mumbai-400 025. Tel No.022-2431 1616 / 2431 1614 |

|

96

|

Dr.Neil J.Borges, (MMC Regn No.082432)

Year 2010 |

c/o Dr.Ranbir Singh

33, Rex Chambers. Walchand Hirachand Marg, Ballard Estate, Mumbai-400 001 |

|

97

|

Dr.Panchal Chandulal Shankarlal (MMC REgn No.47315)

Year 2010 |

c/o Dr.Ranbir Singh

33, Rex Chambers. Walchand Hirachand Marg, Ballard Estate, Mumbai-400 001 |

|

98

|

Dr.Bhavana Bhatia (MMC Regn No.091006)

Year 2010 |

White Cross Medical Institute,

5-A, Meghji Bhavan, 1st Floor, Barrack Road, Mumbai-400 020. Tel No.2200 4291/2200 9985 Fax No.2200 7693 |

|

99

|

Dr.Kumar Sanjiva Shetty

(MMC Regn No. 2007/07/3013

Year 2011

|

Blue Shield Medical Clinic,702/703, Crystal Plaza, opp.Solitaire

Park, Chakala, Andheri (East), Mumbai 400 099.

|

|

100

|

Dr.Bharati J.Rele

(MMC Regn No.64785)

Year 2011

|

Rele Clinic,, The Avenue, 903,904, 905, Navpada, Opp.The Leela,

Marol, Andheri(East), Mumbai 400 059.

Tel No.28336767/6868

|

|

101

|

Dr.Jayant Madhukar Rele- (MMC Regn No.65225)

Year 2011

|

Rele Clinic,, The Avenue, 903,904, 905, Navpada, Opp.The Leela,

Marol, Andheri(East), Mumbai 400 059.

Tel No.28336767/6868

|

|

102

|

Dr.Asmita A.Sarang

(MMC Regn No.2003/10/3555)

|

Aquamarine Medical Solutions, C/o.Lifecare Medical Centre, 2nd

Floor,’Nirav Apartments, Plot No.9, Gulmohar Road No.1, Above PItambari,

Juhu, Vile Parle(W), MUmbai 400 049. Tel No. 2385 9283 - 9819151235

|

|

103

|

Dr.

Kale Ranjeet K (MMC Regn No. 23866)

|

Microcare

Diagnostics Health Centre,

CGS

Colony, Sector 7,

Convenient

Shopping Centre,

Antop

Hill, Wadala (East),

Mumbai

400 037

Tel

No.2403 3744/47

|

|

104

|

Dr. Reshamwala Siraj – (MMC Regn No.64386)Year-2005

Change in address of clinic- 2012

|

Z Clinic, Bldg No.15, Contractor Building, R.No.15, Gr Floor,

Vaju Kotak Marg, Fort, Mumbai 400 001.

Tel No. 022-22641455

Email- drsirajakhtar@yahoo.com

|

|

105

|

Dr.Faizal Deshmukh- (MMC Regn No.62504)

|

Narayan Leela Clinic,

6, Shubham Centre No.2,

Chakala, Andheri (E),

Mumbai 400 099.

Tel No.28395053/28305053

|

|

106

|

Dr.Meeta Mehta – (MMC Regn No.070088)

|

Narayan Leela Clinic,

6, Shubham Centre No.2,

Chakala, Andheri (E),

Mumbai 400 099.

Tel No.28395053/28305053

|

|

107

|

Dr. Rohit Suchak (MMC Regn No.38199)

|

Suchak’s

Clinic,

Shop

No.7, Tulsi1,

Opp.Kd’s

Lo Price Super Market,

Near

Bon Bon Footwear,

Off

J.P.Road,

Andheri

(W), Mumbai 400 053.

|

|

108

|

Dr.Bhavana Bhatia (MMC Regn No.91006)

|

White

Cross Medical Institute,

Suit

309, Avenue, opp.Hotel Leela,

Andheri(E),

Mumbai 400 059.

|

|

109

|

Dr.M.K.E.Memon (MMC Regn No. 38152)

|

(Two facilities)

Kaifak

Medicare

201/214,

Maker Chambers V,

Nariman

Point, Mumbai 400 021.

Kaifak

Medicare,

404,

4th Floor,

Andheri

(E), Mumbai 400 053.

|

|

110

|

Dr.

Pradeep R. Vyas,

MMC Regn No. 56870

|

Sai Kripa

Apartment,

Borivili

(W), Mumbai 400 092.

Tel

No.2891 6469, 2891 1021, 2892 9994

Email id:

cardiologistpradeep vyas@gmail.com

|

|

111

|

Dr.

Santosh H.Bhatia

MMC Regn No

2006/12/3791

|

604/B,

Near Andheri Sports Complex,

Andheri(W), Mumbai 400 058.

Email

id- drsantoshbhatia@gmail.com

|

This Blog is dedicated to all Marine Engineers preparing for MEO class IV exams. The questions covers all functions (Ship Stability, Marine Electro Technology, Marine Engineering Knowledge, Marine Safety and Marine engineering Practice).

Search This Blog

List of DG Shipping approved doctors,Medical examiners in Mumbai for DC endorsement, CDC, COC in Mumbai for Merchant Navy Officers and Seafearers

DG Shipping approved medical examiners, Doctors in Kochi, Ernakulam for seafarers, 2014

Sr. No.

|

Name of the Medical Examiners / Year of Approval

Reference No.

|

Full Style of Facility

|

Remarks

1. Suspension etc.

2. Validity of approval.

3. Next periodical inspection due.

|

1

|

Dr. Divakar Prabhu (Travancore

Year-2001

|

House No.59/4242, "Dwaraka"

Phone-0484-2355257

|

Extended till 15.11.2020

(upto the age of 75 years)

Approval

letter issued vide letter No.7-NT(8)/2010-II dt 11th May, 2011

|

2

|

Dr. G. P. Bhatt

(Travancore-Cochin CMM No.5937)

Year-2001

|

Jairam & Sons 45/364,

Clinic, |

Extended till 4.7.2017.

(upto the age of 75 years) Approval

letter issued vide letter No.7-NT(8)/2010-II dated 4-7th July,

2011.

|

3

|

Dr. S. R. Mohan

Year-2001 |

||

4

|

Dr. P. V. Unnikrishnan

Year-2002 (Travancore-Cochin C MM Regn No.9794)

|

Sakthi Medical Centre, Market Canal Road, Cochin-682 035.

Telephone- 0484-2353783 |

Approval letter issued vide

No.7-NT(8)/2013-II dated 24th December, 2013.

|

5.

|

Dr. K.R. Jayachandran

Year-2003

|

||

6

|

Dr. Arun Kumar

|

||

7.

|

Dr. Shirly

John Year-2005

|

Clinic: PVS Memorial Hospital Ltd. Cochin-682 017

|

|

8

|

Dr. M. Arvind Babu

-------

|

Clinic-Doctors Diagnostic Centre International,

Cohcin-682 011 Phone-0484-2368383/2363000 FAX-0484-2364141 |

|

9

|

Dr. Easa V. K. (MMC Regn No.39581)

Year 2010 |

Metro Medi Centre,

C.C.No.X!/7 10A, yyatil Junction, Kochin-680 011. Tel No.0484 2370416 |

Extended till 18.4.2021.

(upto the age of 75 years)

Approval (extn

)letter issued vide letter No.7-NT(8)/2010-II dt 24th May, 2011

|

Function of Thermostatic Expansion Valve in refrigeration system, Internal and external equalizing valve types with explanation and diagram.

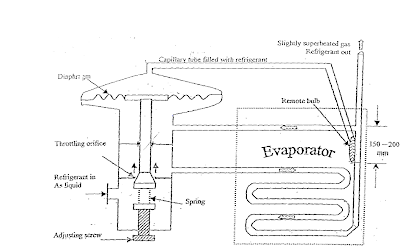

Thermostatic expansion valve is a throttling device used for flow control of refrigerant in the refrigeration system. Throttling is done to reduce the boiling point of the liquid from the condenser. this is achieved by reducing the presure of the refrigerant as it is metered through the small orifice of the throttling device. As the pressure reduces, the boiling temperature of the refrigerant also reduces.

So the main functions of a TEV is to

- To meter the liquid refrigerant from liquid into the evaporator at a rate suitable to maintain the designed operating pressure at different load condition.

- To mainatain the difference of pressure between high and low pressure side of the refrigerant.

- to amintain a constant degree of superheat at the outlet of evaporator.

Systems using thermostatic expansion valves use basically one of two types of valves: internally equalized and externally equalized. The two types of expansion valves are similar, but not interchangeable, both types of expansion valves are Installed in the system to lower the pressure before the refrigerant enters the evaporator. The reduction in pressure is accomplished simply by passing the refrigerant through a small hole (orifice), but the opening and closing of the orifice must be controlled to compensate for changes in pressure and temperature, the temperature of refrigerant leaving the evaporator is sensed by a thermal bulb and capillary tube which moves the valve seat via a diaphragm and actuating pins. Internally equalized expansion valves permit refrigerant pressure from the outlet side of the orifice to pass through an internal passage and push against the underside of the diaphragm.Externally equalized expansion valves have a line connected to the outlet side of the evaporator and refrigerant pressure passes through this line to push against the underside of the diaphragm

Three forces which govern the thermal expansion valve’s operation are

1) The power element and remote bulb pressure (P1)

2) the evaporator pressure (P2), and

3) the superheat spring equivalent pressure (P3).

We will deal with both types of TEV, 1) Internally equalized TEV 2) Externally Equalized TEV

1) Internal Equalized Expansion Valve

(Eventhough R12 is banned as per the montreal protocal, we have used R12 refigerant for the purpose of calculation)

Three conditions present themselves in the operation of this valve: first, the balanced forces; second, an increase in superheat; third, a decrease in superheat. The remote bulb and the power element make up a closed system (power assembly), and in the following discussion, it is assumed that the remote bulb and power element are charged with the same refrigerant as that in the system. The remote bulb and Power element pressure which corresponds to the saturation pressure of the refrigerant gas temperature leaving the evaporator, moves the valve pin in the opening direction.

Opposed to this opening force on the underneath side of the diaphragm and acting in the closing direction are two forces: (1) the force exerted by the evaporator pressure and (2) that exerted by the superheat spring. In the first condition, the valve will assume a stable control position when these three Forces are in balance (that is, when P1 = P2 + P3). In the next step, the temperature of the refrigerant gas at the evaporator outlet (remote bulb location) increases above the saturation temperature corresponding to the evaporator pressure as it becomes superheated. The pressure thus generated in the remote bulb, due to this higher temperature, Increases above the combined pressures of the evaporator pressure and the superheat spring (P1 greater than P2 + P3) And causes the valve pin to move in an opening direction. Conversely, as the temperature of the refrigerant gas leaving the evaporator decreases, the pressure in the remote bulb and Power assembly also decreases and the combine evaporator and Spring pressure cause the valve pin to move in a closing Direction (P1 less than P2 + P3).

For example, when the evaporator is operating with R12 at a Temperature of 40EF or a pressure of 37 Psig and the refrigerant gas leaving the evaporator at the remote bulb Location is 50EF a condition of 10EF superheat exists.

Since the remote bulb and power assembly are charged with the same refrigerant as that used in the system (R12), its Pressure (P1) will follow its saturation pressure temperature characteristics. With the liquid in the remote bulb at 50ºF the pressure inside the remote bulb and power assembly will be 46.7 Psig acting in an opening direction.

Beneath the diaphragm and action a closing direction is the evaporator pressure (P2) of 37 Psig and the spring pressure (P3) for a 10EF superheat setting of 9.7 Psig (37 + 9.7 = 46.7) making A total of 46.7 Psig. The valve is in balance, 46.7 Psig Above the diaphragm and 46.7 Psig below the diaphragm. changes in load, increasing the superheat, will cause the thermal expansion valve pin to move in an opening direction. Conversely, a change, decreasing the superheat, will cause the thermal valve pin to move in a closing direction.

2)External Equalized Expansion Valve

When the pressure drop through the evaporator is of any consequence, i.e., in general a pressure drop equivalent to 3 degrees in the air-conditioning range, 2 degrees in the commercial temperature range, and 1 degree in the low temperature range, it will hold the thermal expansion valve in a relatively "restricted" position and reduce the system capacity, unless a thermal expansion valve with an external equalizer is used. The evaporator should be selected for the operating conditions and the thermal expansion valve selected and applied accordingly.

For example, an evaporator is fed by a thermal expansion valve with an internal equalizer, where a sizeable pressure drop of 10 Psig is present. The pressure at point "c" is 27 Psig or 10 Psig lower than at the valve outlet, point "a"; however, the pressure of 37 Psig at point "a" is the pressure acting on the lower side of the diaphragm in a closing Direction. With the valve spring set at a compression equivalent to 10EF superheat or a pressure of 9.7 Psig, the required pressure above the diaphragm to equalize the forces is (37 + 9.7) or 46.7 Psig. This pressure corresponds to a saturation temperature of 50EF. It is evident that the refrigerant temperature at point "c" must be 50EF if the valve is to be in equilibrium. Since the pressure at this point is only 27 Psig and the corresponding saturation temperature is 28EF a superheat of 50EF - 28EF or 22 Degrees is required to open the valve. This increase in superheat, from 10 to 22 degrees make it necessary to use more of the evaporator surface to produce this higher superheated refrigerant gas. Therefore, the amount of evaporator surface available for absorption of latent heat of vaporization of the refrigerant is reduced; the evaporator is starved before the required superheat is reached. Since the pressure drop across the evaporator, which caused this high superheat condition, increases with the load because of friction, this "restriction" or "starving" effect is increased when the demand on the thermal valve capacity is greatest.

In order to compensate for an excessive pressure drop through an evaporator, the thermal expansion valve must be of the external equalizer type, with the equalizer line connected either into the evaporator at a point beyond the greatest pressure drop or into the suction line at a point on the compressor side of the remote bulb location.

In general and as a rule of thumb, the equalizer line should be connected to the suction line at the evaporator outlet. If the external equalizer type of thermal expansion valve is used, with the equalizer line connected to the suction line, the true evaporator outlet pressure is exerted beneath the thermal valve diaphragm, the operating pressures on the valve diaphragm are now free from any effect of the pressure drop through the evaporator, and the thermal valve will respond to the superheat of the refrigerant gas leaving the evaporator.

When the same conditions of pressure drop exists in a system with a thermal expansion valve which has the external equalizer feature, the same pressure drop still exists through the evaporator; however, the pressure under the diaphragm is now the same as the pressure at the end of the evaporator, point "c", or 27 Psig.

The required pressure above the diaphragm for equilibrium is 27 + 9.7 or 36 Psig. This pressure, 36.7 Psig, corresponds to a saturation temperature of 40EF and the superheat required is now (40EF - 28EF) 12 degrees. The use of an external equalizer has reduced the superheat from 22 to 12 degrees. Thus, the capacity of a system, having an evaporator with a sizable pressure drop, will be increased by the use of a thermal expansion valve with the external equalizer as compared to the use of an internally equalized valve. As pointed out Earlier the external equalizer line must be installed beyond the point of greatest pressure drop.

So external equalizing line is used when there is a marginal pressure drop inside the evaporator, so we can avoid starvation of refrigerant

So the main functions of a TEV is to

- To meter the liquid refrigerant from liquid into the evaporator at a rate suitable to maintain the designed operating pressure at different load condition.

- To mainatain the difference of pressure between high and low pressure side of the refrigerant.

- to amintain a constant degree of superheat at the outlet of evaporator.

Systems using thermostatic expansion valves use basically one of two types of valves: internally equalized and externally equalized. The two types of expansion valves are similar, but not interchangeable, both types of expansion valves are Installed in the system to lower the pressure before the refrigerant enters the evaporator. The reduction in pressure is accomplished simply by passing the refrigerant through a small hole (orifice), but the opening and closing of the orifice must be controlled to compensate for changes in pressure and temperature, the temperature of refrigerant leaving the evaporator is sensed by a thermal bulb and capillary tube which moves the valve seat via a diaphragm and actuating pins. Internally equalized expansion valves permit refrigerant pressure from the outlet side of the orifice to pass through an internal passage and push against the underside of the diaphragm.Externally equalized expansion valves have a line connected to the outlet side of the evaporator and refrigerant pressure passes through this line to push against the underside of the diaphragm

|

| Internal Equalizing TEV |

|

| External Equalizing TEV |

Three forces which govern the thermal expansion valve’s operation are

1) The power element and remote bulb pressure (P1)

2) the evaporator pressure (P2), and

3) the superheat spring equivalent pressure (P3).

We will deal with both types of TEV, 1) Internally equalized TEV 2) Externally Equalized TEV

1) Internal Equalized Expansion Valve

(Eventhough R12 is banned as per the montreal protocal, we have used R12 refigerant for the purpose of calculation)

Three conditions present themselves in the operation of this valve: first, the balanced forces; second, an increase in superheat; third, a decrease in superheat. The remote bulb and the power element make up a closed system (power assembly), and in the following discussion, it is assumed that the remote bulb and power element are charged with the same refrigerant as that in the system. The remote bulb and Power element pressure which corresponds to the saturation pressure of the refrigerant gas temperature leaving the evaporator, moves the valve pin in the opening direction.

Opposed to this opening force on the underneath side of the diaphragm and acting in the closing direction are two forces: (1) the force exerted by the evaporator pressure and (2) that exerted by the superheat spring. In the first condition, the valve will assume a stable control position when these three Forces are in balance (that is, when P1 = P2 + P3). In the next step, the temperature of the refrigerant gas at the evaporator outlet (remote bulb location) increases above the saturation temperature corresponding to the evaporator pressure as it becomes superheated. The pressure thus generated in the remote bulb, due to this higher temperature, Increases above the combined pressures of the evaporator pressure and the superheat spring (P1 greater than P2 + P3) And causes the valve pin to move in an opening direction. Conversely, as the temperature of the refrigerant gas leaving the evaporator decreases, the pressure in the remote bulb and Power assembly also decreases and the combine evaporator and Spring pressure cause the valve pin to move in a closing Direction (P1 less than P2 + P3).

For example, when the evaporator is operating with R12 at a Temperature of 40EF or a pressure of 37 Psig and the refrigerant gas leaving the evaporator at the remote bulb Location is 50EF a condition of 10EF superheat exists.

Since the remote bulb and power assembly are charged with the same refrigerant as that used in the system (R12), its Pressure (P1) will follow its saturation pressure temperature characteristics. With the liquid in the remote bulb at 50ºF the pressure inside the remote bulb and power assembly will be 46.7 Psig acting in an opening direction.

Beneath the diaphragm and action a closing direction is the evaporator pressure (P2) of 37 Psig and the spring pressure (P3) for a 10EF superheat setting of 9.7 Psig (37 + 9.7 = 46.7) making A total of 46.7 Psig. The valve is in balance, 46.7 Psig Above the diaphragm and 46.7 Psig below the diaphragm. changes in load, increasing the superheat, will cause the thermal expansion valve pin to move in an opening direction. Conversely, a change, decreasing the superheat, will cause the thermal valve pin to move in a closing direction.

2)External Equalized Expansion Valve

When the pressure drop through the evaporator is of any consequence, i.e., in general a pressure drop equivalent to 3 degrees in the air-conditioning range, 2 degrees in the commercial temperature range, and 1 degree in the low temperature range, it will hold the thermal expansion valve in a relatively "restricted" position and reduce the system capacity, unless a thermal expansion valve with an external equalizer is used. The evaporator should be selected for the operating conditions and the thermal expansion valve selected and applied accordingly.

For example, an evaporator is fed by a thermal expansion valve with an internal equalizer, where a sizeable pressure drop of 10 Psig is present. The pressure at point "c" is 27 Psig or 10 Psig lower than at the valve outlet, point "a"; however, the pressure of 37 Psig at point "a" is the pressure acting on the lower side of the diaphragm in a closing Direction. With the valve spring set at a compression equivalent to 10EF superheat or a pressure of 9.7 Psig, the required pressure above the diaphragm to equalize the forces is (37 + 9.7) or 46.7 Psig. This pressure corresponds to a saturation temperature of 50EF. It is evident that the refrigerant temperature at point "c" must be 50EF if the valve is to be in equilibrium. Since the pressure at this point is only 27 Psig and the corresponding saturation temperature is 28EF a superheat of 50EF - 28EF or 22 Degrees is required to open the valve. This increase in superheat, from 10 to 22 degrees make it necessary to use more of the evaporator surface to produce this higher superheated refrigerant gas. Therefore, the amount of evaporator surface available for absorption of latent heat of vaporization of the refrigerant is reduced; the evaporator is starved before the required superheat is reached. Since the pressure drop across the evaporator, which caused this high superheat condition, increases with the load because of friction, this "restriction" or "starving" effect is increased when the demand on the thermal valve capacity is greatest.

In order to compensate for an excessive pressure drop through an evaporator, the thermal expansion valve must be of the external equalizer type, with the equalizer line connected either into the evaporator at a point beyond the greatest pressure drop or into the suction line at a point on the compressor side of the remote bulb location.

In general and as a rule of thumb, the equalizer line should be connected to the suction line at the evaporator outlet. If the external equalizer type of thermal expansion valve is used, with the equalizer line connected to the suction line, the true evaporator outlet pressure is exerted beneath the thermal valve diaphragm, the operating pressures on the valve diaphragm are now free from any effect of the pressure drop through the evaporator, and the thermal valve will respond to the superheat of the refrigerant gas leaving the evaporator.

When the same conditions of pressure drop exists in a system with a thermal expansion valve which has the external equalizer feature, the same pressure drop still exists through the evaporator; however, the pressure under the diaphragm is now the same as the pressure at the end of the evaporator, point "c", or 27 Psig.

The required pressure above the diaphragm for equilibrium is 27 + 9.7 or 36 Psig. This pressure, 36.7 Psig, corresponds to a saturation temperature of 40EF and the superheat required is now (40EF - 28EF) 12 degrees. The use of an external equalizer has reduced the superheat from 22 to 12 degrees. Thus, the capacity of a system, having an evaporator with a sizable pressure drop, will be increased by the use of a thermal expansion valve with the external equalizer as compared to the use of an internally equalized valve. As pointed out Earlier the external equalizer line must be installed beyond the point of greatest pressure drop.

So external equalizing line is used when there is a marginal pressure drop inside the evaporator, so we can avoid starvation of refrigerant

How Bulbous bow increases the efficiency of a ship and what are its major functions and advantages?

Bulbous bow reduces the Hull wave making resistance of a ship, which is the major residuary frictional resistance of a ship. It reduces the bow wave, due to the wave generated by the bulb itself, making the ship more efficient in terms of energy. Here Blue and Green lines shows the wave generated by the bulbous bow of the ship and stem of the ship respectively. The Red line shows the resultant wave, which is reduced in amplitude due to the interference of one on other. Thus the hull wave making resistance is reduced. So more efficient and lesser fuel oil consumption.

So the major functions and advantages of a bulbous bow ships are

So the major functions and advantages of a bulbous bow ships are

- Reduces the bow wave, due to the wave generated by the bulb itself, making the ship more efficient in terms of energy

- Increases the ship’s waterline length, slightly increasing the ship speed, reducing the installed power requirements and so the fuel oil consumption

- Works as a robust “bumper" in the event of a collision

- Allows the installation of the bow thrusters at a foremost position, making it more efficient

- Allows a larger reserve of flotation

- A larger ballast capacity of fore peak tank

- Extra protection for panting and pounding

Ship's different movements in sea - explanation with diagram - Surging, Swaying, Heaving, Rolling, Pitching and Yawing -

Here is the answer for the question ' What are the different types of movements or motions of ship at sea?'

Ship has 6 motions at sea- 3 linear motions and 3 angular or rotational motions

Ship has 6 motions at sea- 3 linear motions and 3 angular or rotational motions

Linear motion Rotational motion

Surging is motion along the longitudinal axis.

Rolling is motion around the longitudinal axis.

Swaying is motion along the transverse axis

Rotational Motions

Pitching is motion around the transverse axis.

Heaving is motion along the vertical axis.

Yawing is motion around the vertical axis.

Function of PV Breaker (Pressure Vacuum Breaker) in Inert Gas (IG system) line onboard ship

Pressure Vacuum Breaker or usually known as PV Breaker is a safety measure used in the IG line on deck. The major functions of a PV breaker are

1) Abnormal rise of Pressure in Cargo tanks when loaded specified rate of gas outlets

2) Abnormal rise of Pressure in Cargo tanks when cargo is unloaded beyond specified rate of the inert gas blower

3) Abnormal rise or drop of pressure in cargo tanks when the breather valve doesnot operate properly for the fluctuation of the pressure in cargo tanks due to variation in atmospheric and sea water temperatures

Operation

1) When Pressure Rises

When the pressure in the cargo oil tanks rise, the seal liquid rises in the inner pipe. At this time , if the pressure beyond the specific capacity of the breaker, the seal liquid will push out of the pipe to let the pressure inside the be out

2) When Pressure drops

When the pressure in the cargo oil tanks fall, the seal liquid rises in the outer pipe. If the pressure beyond the specific capacity of the breaker, the seal liquid is drown into the cargo oil tanks, and atmospheric air will be inhaled in the tank

Subscribe to:

Posts (Atom)

breaker.PNG)